Offshore charging systems may be in their infancy, but with continued development and collaboration, workable and practical solutions away from port could soon become a reality.

Aside from the sustainability and efficiency benefits of marine electric powertrains, zero-emission vessels improve the air quality in harbors and ports. Onshore charging technology is now quite well established but there aren’t many offshore solutions. The newness of the sector and its technology might explain why.

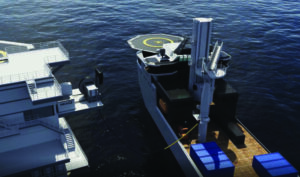

“I think the reason why there are so few solutions is that there’s no huge market for this yet,” says Håvard Vollset Lien, VP of research and innovation at Vard Group. Vard’s Ocean Charger project scooped the Vessel Charging Innovation of the Year Award at the Electric & Hybrid Marine Awards in 2023. Working with a consortium of partners, the company aims to install an offshore charging station network alongside existing onboard technologies for zero-emission maintenance at offshore wind farms. Offshore wind farms and the crew transfer vessels (CTVs) that serve them are currently where the best opportunities for the technology lie. However, its experimental nature makes development challenging.

“It’s really difficult to do,” confirms Paul Cairns, managing director of marine power systems and engineering company MJR Power & Automation. “It’s like plugging your Tesla into a charger at the service station and driving around the car park at 80km/h while somebody’s throwing buckets of seawater at you.” In partnership with Blackfish Engineering and Tidal Transit, and as part of the Clean Maritime Demonstration Competition (CMDC) run by the UK’s Department for Transport and Innovate UK, MJR has developed and built a prototype in-air, gravity-fed ‘funnel’ CTV charging system that can be mounted on a turbine or an offshore substation (OSS). Onshore harbor trials at the Port of Blyth in 2023 were successful, using Tidal Transit’s CTV, Tia Elizabeth. “Offshore tests will follow in Q1 2024, with plans to upscale the system with higher power to cope with larger service operation vessels (SOVs),” says Cairns.

Oasis Marine has been developing its Oasis Power Buoy (OPB) offshore charging system for more than three years. It recently successfully transferred power to a CTV during CMDC-initiated tests at the Port of Peterhead, along with support from 23 Degrees Renewables, GulfXStream and JifMar Scotland. Mooring tests were also staged, in which the CTV was successfully moored to the OPB.

“This was the first in a series of tests, and one of the things we were able to prove was the fundamental operation of the buoy and the pull across of the power head onto the vessel,” says George Smith, Oasis Marine’s managing director.

“Like development of any new technology, it is a challenge to develop, deploy and demonstrate safe and reliable operation of these systems for the first time,” says Lauren Hadnum, clean maritime manager at the Offshore Renewable Energy (ORE) Catapult, a technology innovation and research center in the UK. “This is why projects by companies such as MJR and Oasis Marine, carried out under CMDC and ZEVI (Zero Emission Vessels and Infrastructure) funding, are critical. They demonstrate technology performance to industry to enable valuable learning, prior to deployment, and accelerate uptake and acceptance of these systems.”

Standardized connectors

Technology barriers include the physical charging connectors. “None of the off-the-shelf connectors are really suitable,” explains Smith. Subsea connectors are available but are designed to work at depths of 100m of seawater and mating five or six times. “We’re looking for something that will operate at the surface, in the splash zone, sometimes in salt water, sometimes in air, and can meet at least 5,000 times,” he says. Oasis Marine is working with the Carbon Trust on a standardized connector, which is another huge topic. “There is now a general agreement around the interface to CTVs,” Smith says, adding that for any individual wind farm there could be several CTVs operating during a year, so a standardized connector is important.

Automation is another key enabler, to make charging safer for vessel crews. “We have hands-free connections and our system is based fully on not having the crew handling things,” explains Cairns. “The vessel takes remote control of the cable deployment system after authorization. Once it’s connected, charging is automated.”

Lien confirms that teams at Vard are looking into wireless charging technology. Nick McCarthy, technical specialist at UK low-emission vehicle research consultancy Cenex, says that technical challenges for offshore charging solutions include the system power rating. “Static normalization between the vessel and the charge point needs to be overcome, with no arcing between the two,” he explains. “There need to be appropriate, safe grounding technologies between the two systems.”

Hadnum says, “Systems currently tend to focus on CTV (150kW+) or SOV (700kW+) power, and we are likely to see MW-scale solutions to support SOV operations. There is still potential for these systems to scale up significantly to support other vessels, and companies such as Verlume are also investigating the potential role of batteries in these systems.”

MJR’s charger is designed for a maximum capacity of 2MW, with an SOV system rated at up to 8MW. Oasis’s OPB is also rated at 2MW, while Vard’s system has a maximum of 6.3MW. Kristian Borum Jørgensen, CEO of Stillstrom – whose charging buoy can charge an SOV-sized vessel – says the company’s offshore charging development is focused on delivering 4-6MW AC. “This will match power requirements for SOVs to perform their daily work.”

Other difficulties include turbine retrofit capabilities. “Older turbines not designed to have chargers installed may require significant modification,” says Leo Hambro, a director at Tidal Transit. “On some, it will not be commercially viable, but new turbines and OSS can be built with chargers in mind.”

Hadnum believes the need for offshore charging will increase, and the technologies will develop in line with vessel requirements. “Early concepts have mostly focused on CTVs and SOVs that tend to be in close proximity to the infrastructure, but these systems are potentially applicable to a wider segment of the maritime market,” she says. This is a particularly important area for the development of standards and regulations. “Work by the Carbon Trust and organizations such as DNV is vital to support the rollout of this infrastructure to a wider user base.”

Regulatory challenges may be overcome as more systems are developed. “Offshore power and charging doesn’t have any rules yet, but they are in development,” Cairns says. MJR is currently going through a DNV approval-in-principle program.

“Although regulations are key to driving the broad decarbonization agenda, we do also see that private stakeholders such as ports, and vessel owners and operators, are moving quickly to lower their operation footprint,” says Jørgensen. “Offshore charging is becoming a very relevant technology to adapt.”

Collaborative approach

The planning, location and maintenance of offshore charging systems looks set to require a collaborative approach. “Depending on the subsidy scheme a wind farm was built under, there may be restrictions on the extraction of power pre-meter without penalties,” says Hambro. “Charging buoys also require specialist mooring systems and, in some cases, additional seabed leasing.”

Feed studies such as those being carried out by MJR help to identify suitable locations, and other optimized installation models aim to determine possible sites. Smith reports that practical and safety aspects dictate where charging buoys are sited. “We are looking at an optimized installation within an offshore wind farm, because CTVs need to be within 10 minutes of where personnel are working, in case of emergency,” he says.

“As the field is in its nascent stages, formalized plans for maintenance and operational management are still evolving,” explains Andy Martin, chief commercial officer at intelligent energy management and storage technologies specialist Verlume. “Financial and logistical aspects of energy billing and ownership at these charging stations also present unique challenges.”

Jørgensen explains that Stillstrom is developing its offshore charging solutions to serve as green vessel ‘parking lots’ at anchorage sites near populated port cities. “The objective is to offer electricity to vessels sitting at anchor, replacing consumption of marine fuels with electricity,” he says. Implementing these parking lots is complex and requires a number of stakeholders. “We manage this by engaging with regulators, administration bodies and relevant national and local stakeholders. Technical challenges such as grid restrictions and green power availability impact development,” he adds.

Getting ready

In terms of market readiness, McCarthy says, offshore charging technology is currently at a technical readiness level of around 6 or 7. “TRL 6 or 7 is when you’re starting to put things into real working conditions to see what happens,” he explains. A TRL of 8 indicates readiness for a limited trial with up to five vessels operating for a year using the technology. If that trial is successful, a commercial product can be sold.

Cairns says MJR is staging an offshore pilot trial in Q1 2024. It also expects to sell a 1.2MW charger to a wind farm to support its ZEVI project with Tidal Transit, which involves building or converting a CTV to electric, with an offshore charger installed at the wind farm. He expects CTV commercialization to happen in Q3 2024, with SOV to follow a year later.

“We think we’d be ready for market launch in one to two years,” Smith says. “We will see the first systems installed from 2025,” says Hadnum. “However, until 2030, the focus will likely be on offshore wind support vessel charging,” she adds.

Vard has recently simulated its charging solution in a ship simulator, testing the connection and de-connection systems. “In March 2024, we are testing the full-scale prototype in the North Sea, which will be very close to the end product,” says Lien. Vard expects to take firm orders for the Ocean Charger in spring 2024. As to when offshore charging technology could enter a more mainstream phase, Lien remains expectant.

“I will wait and see, because I believe we will see a flattening out of battery energy density development. This has been tremendous in the last 10 years, but new battery technology is coming, which is safer but not any more energy dense. This means we soon may have reached the limitation on what we can use batteries for on a ship for a while.”

This article was originally published in the January 2024 issue of Electric and Hybrid Marine Technology. To view the magazine in full, click here.