Navtek Naval Technologies has laid the groundwork for future low emissions harbor operations with its new all-electric tug, ZEETUG (zero emissions electric tug). According to the company, the project started with two seemingly straightforward requests. Customer Gisas Shipbuilding asked for harbor tugs that were both lower emission and smaller in size than its previous fleet. This request was driven by a need to meet stricter environmental requirements and an ability to navigate the tight confines of the Port of Tuzla, Istanbul, where they would operate.

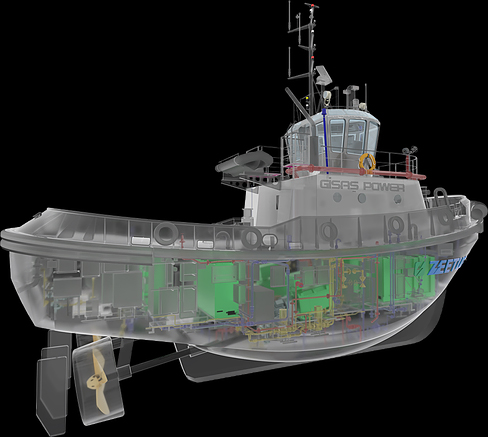

Built at Navtek’s parent company’s TK Tuzla Shipyard, the first ZEETUG, Gisas Power, went into service this year, operating in the shipyard zone at the Port of Tuzla. Designated as a ZEETUG-30 design for its 32 tons of bollard pull, the vessel has an overall length of 18.7m (61.4ft), beam of 6.7m (22ft), depth of 4.7m (15.4ft) and design draught of 3.5m (11.5ft), with a service speed of 10kts. Navtek notes that thanks to a modular system, the ZEETUG concept has an integrated electrical propulsion system that can be tailored to a client’s specific operation profile (from 5-ton BP to 75-ton BP).

The ZEETUG-30 draws its power from two 1,450kW lithium-ion battery packs supplied by Corvus Energy. For safety, the tug has two redundant battery rooms, one forward and one aft, which are maintained at a constant temperature by an air-cooling system. The vessel has been designed and built according to Turkish Lloyd’s rules, and meets any IACS member classification society’s valid and related requirements.

To optimize electric power consumption, analyze the operational profile and extend the range of the tug, Navtek says it has designed its Smart Tug Energy Management System (STEMS) to work in conjunction with the propulsion system. This software monitors the boat’s performance via an onboard data acquisition system, tracking tug speed, motor speed, power consumption, battery and motor temperature in addition to battery state of charge, while also providing feedback and suggested actions to the captain. Additionally, remote monitoring and diagnostics enable technicians and engineers to resolve any issues in real time. The company says that fleetwide updates can be completed in a matter of hours.

A full charge for the tug can be accomplished in one hour via a dedicated quick-charging station (QCS). A Navtek representative says, “The time it takes to charge a ZEETUG varies based on the charger used, like other electrical devices. We adjust the technical characteristics of each tug according to the existing operating profile and needs/requirements of our clients.” The QCS is also designed and built by Navtek.

A full charge for the tug can be accomplished in one hour via a dedicated quick-charging station (QCS). A Navtek representative says, “The time it takes to charge a ZEETUG varies based on the charger used, like other electrical devices. We adjust the technical characteristics of each tug according to the existing operating profile and needs/requirements of our clients.” The QCS is also designed and built by Navtek.

Compared with similarly sized diesel tugs, Navtek expects the electric vessels to save 210 tons of CO2 and 9 tons of NOX emissions in a year. It also highlights that the 85% lower operating cost of its full-electric propulsion system is a considerable benefit for operators, and provides a short return on investment. Furthermore, despite a high power output, the electric drive means significant increase in crew comfort levels, with very low noise and vibrations.

Navtek worked with a variety of partners on the project, including BMA Technology (the electrical systems integrator), Corvus Energy (the battery supplier) and ABB (the drive and converter supplier). Currently, the company has two further 30-ton BP and one 45-ton BP ZEETUGs in its order book for Gisas. The construction on these follow-on vessels will start in 2020.