AYK (Booth 7050) has been busy answering questions about its plans to build a new gigafactory at the famous Oak Ridge K25 site location of the Manhattan Project – now part of East Tennessee Technology Park – at this year’s show. The new-build project will complement AYK’s 5,000m2 factory in Zhuhai, China, which opened in 2023.

The China plant has a production capacity of 300MWh a year (with the ability to expand to 1GWh a year) with Oak Ridge following a similar model. In total, AYK Energy expects orders to exceed 100MW in 2024, tripling sales in 2023.

“We are disrupting the market with our vision of a safe, low-cost and highly innovative range of batteries,” AYK Energy’s founder, Chris Kruger, told Electric & Hybrid Marine Technology International.

According to Kruger, the new USA factory stands to benefit from Oak Ridge’s free trade zone status, enabling AYK to not only serve the burgeoning USA market for ferries, tug boats and workboats, but also the international market with no duties on exports.

The plant project is being led by Ed Carney, a native New Yorker who now lives in Tennessee. The company is already working with local stakeholders and trade unions on the project and is aiming to employ up to 150 skilled workers supported by an apprenticeship program to train young people in an industry of the future.

“We are massively excited by the US market for coastal, inland marine and Great Lakes vessels,” says Kruger. “There is a growing rumble of demand in the USA that is only getting louder. Our concept is for the Oak Ridge factory to serve that demand, especially for the high-speed ferries, hybrid vessels and specialized craft needed for the offshore wind energy industry. We’ve proved what we can do in the short sea inland marine industry by supplying one of the most high-profile electric projects in Europe – with the delivery of the H2 Barge 2 hydrogen-powered container vessel. Now we take another step into the USA Jones Act market.”

AYK has also seen a lot of interest in its H2 Barge 2, which it recently handed over to Future Proof Shipping at Holland Shipyards Group (HSG) in Werkendam earlier this year. The zero-emission barge is seen as a trailblazer for the marine industry and features two high-density AYK DNV-approved Aries 88 lithium batteries. The 125Wh/kg batteries were installed as part of a complete retrofit at HSG which saw the vessel’s diesel engine replaced with a propulsion system consisting of PEM fuel cells, hydrogen storage, AYK’s battery packs and an electric drivetrain.

Following the retrofit, the vessel now has a cargo capacity of 190 TEU and will operate on the busy Rotterdam-Duisburg route along the Rhine.

“The battery system on this vessel is easy to install, built to exceed class requirements, with a higher density than many other batteries on the market,” explained Kruger. “AYK is one of the few battery manufacturers to exclusively use lithium iron phosphate (LFP) and we have developed a system where the LFP chemistry is safer, with greater energy density than nickel manganese cobalt (NMC).”

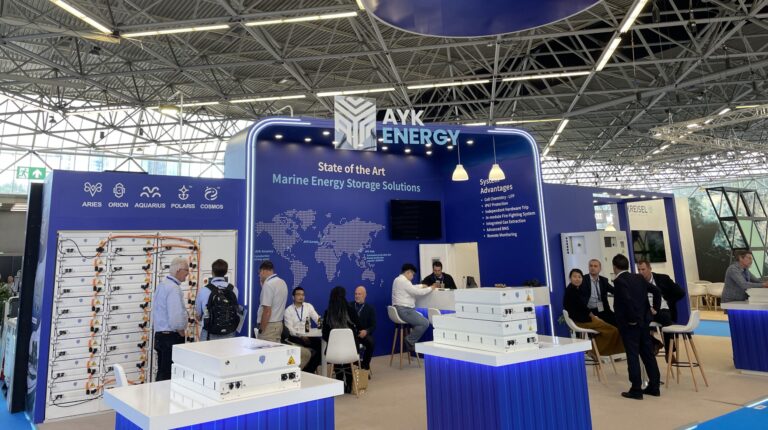

Finally, AYK has also been showcasing its first aluminum enclosure battery, complementing its steel battery range (where weight is not critical), at this year’s show. The aluminum battery is targeted at the fast ferry market where lighter weight is required. The battery will feature a new cell produced by AYK’s partner Eve, a combination which will enable up to 30% weight savings.

“This aluminum enclosure battery with the new cell technology is a game-changer,” believes Kruger. “No other manufacturer has this technology or engineering relationship with Eve. The battery will drive down cost and ramp up power for high-speed catamaran ferries worldwide. We are already selling these batteries and are close to type approval.

“We made a conscious decision to establish ourselves in China. Now we have access to the latest technological innovations, and we are close to our supply chain, which allows for constant advancement of our product range,” he adds. “This supply chain is enabling us to grow and innovate LFP batteries much faster. We are now taking this know-how to the global market, supplying a very wide range of vessels from superyachts to ferries to tug boats.”

Overall, Kruger sees the US factory as the company’s “boldest move yet” and one which will enable the company to drive decarbonization faster and more affordably.

“Throughout time, the key to the electric industry – from the days of the current wars between Edison, Westinghouse and Tesla – has been to democratize its use,” he says. “At AYK, we believe with our knowledge, supply chain and LFP technology, we can play a decisive role in bringing marine batteries to a much bigger mass market than ever before. We have a dream that marine batteries will become not just a luxury or a novelty, but a low-cost, easy-to-use necessity for all vessel operators serious about decarbonization.”

Booth 7050