Two waterjet manufacturers have recently released details of new hybrid systems, HamiltonJet and Doen.

The former’s system, the Electro-Hybrid Drive (EHX) is a package of electric motors and control electronics, designed to work in conjunction with waterjets and traditional, IC engines.

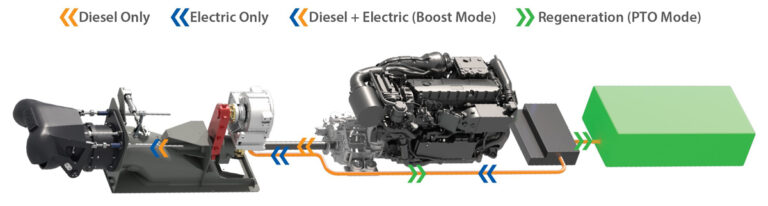

The company said the control system manages the hybrid energy flow between engines, batteries and motors, while charging and discharging the batteries as required. It can be run either fully automatically, or via four manually selectable modes of operation – diesel only, electric only, charging or electric boost. All of these functions are accessed via a single display, and the system can be configured for pure electric vessels.

Company CEO Ben Reed noted, “When it comes to hybrid electric solutions, we know one size definitely does not fit all. That’s why we’ve created a system that’s scalable to individual vessel projects. Motors, battery capacity and components are all specifically selected based on bespoke need. It means we can ensure the very best outcome for the lowest cost.”

Offering a different solution to the same integration challenges, Australian firm Doen has unveiled details of a hybrid-ready waterjet, which incorporates a power take in (PTI) equipped with a clutch to accept an electric drive input, which can be engaged or disengaged when needed.

The company said this approach eliminates the need for an expensive hybrid-ready marine transmission, special in-series transmission products or in-series electric motors between engine and gearbox, and provides a simple and cost-effective device for combining and converting diesel and electric power at the waterjet.

The ECS400 control platform is readily able to interface with an electric motor, power management system and diesel engine. Doen stated that, from a captain’s point of view, the propulsion and ship’s control in the wheelhouse remain unchanged, regardless of the specific mode of operation.

Meanwhile, fully integrated electric marine drives continue to arrive to market, with the latest coming from Voith, with its electric Voith Schneider Propeller (eVSP). The company said that the main benefits of its new system are high efficiency and a reduction in complexity, thanks to the integration of a permanent magnet motor with the propeller.

Voith said that the drive system combines the technology of its existing VSP with over a decade of electrical know-how gained from development of the Voith Inline Thruster (VIT). It also stated that the integration of the motor into the propeller reduces the volume of lubricating oil needed for a vessel’s propulsion system, while the lack of transmission gears enables stepless operation and virtually loss-free conversion of power from the motor to the propeller.