German company Volabo hopes its 48V drive motor technology will change the tendency for 48V motor systems to be found in mild-hybrid automotive applications.

Initially developed with passenger car applications in mind, the company has decided to launch the first production version of its ISCAD (Intelligent Stator Cage Drive) V50 – which combines low-voltage operation without the downsides of very high-current draw at high power outputs usually associated with such motors – into the marine market.

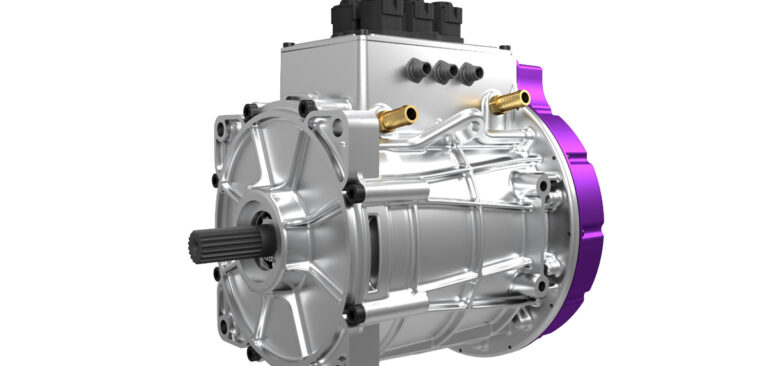

Volabo’s motor concept centers around a completely new approach to the construction of the stator for an induction motor. Where in a conventional motor, the stator consists of multiple copper windings arranged in the slot gaps of the stator, this motor doesn’t. Instead, it uses a ‘cage’ of solid conductors around the internal perimeter of the stator. Hence the name ISCAD.

Key to the concept is that each stator bar is individually driven by power electronics directly mounted to the motor housing, giving exceptional flexibility in terms of the number of motor poles and allowing for dynamic shifting of the number of poles when the motor is in operation.

The V50 has a nominal rating of 50kW and peak output of 80kW, which the company noted makes it ideal for craft such as work boats, where electric propulsion is growing in popularity.

Additionally, thanks to being only 48V, many of the concerns surrounding high-voltage wiring are removed making it suitable for retrofitting to existing vessels. Additionally, running at 48V means low voltage semi-conductors are used in the power electronics, which are more efficient than high-voltage versions.

Complete with its integrated control unit, the entire motor weights 45kg. Volabo said that it can be mounted either vertically or horizontally, thanks to a reinforced end shield, allowing for use in a variety of drive arrangements including sail drives. The first production units are due to ship in December.