There is a widely appreciated barrier to the greater uptake of electric vessels: the cost. Builds will never be as cheap as we want, but with the energy storage solution in some cases making up to three-quarters of the total propulsion system cost, there’s always going to be a particular focus on the battery cost element of every electric/hybrid project.

The cost of lithium batteries has dramatically decreased over the last 10 years, and with global demand from the automotive sector, predictions suggest battery cost will continue to drop as manufacturers ramp up production – great news for e-mobility on the water!

But in the wake of the automotive EV boom, used EV batteries can find themselves homeless, even though they are in a great state of health. Around the world, the batteries removed from EVs that are being dismantled prematurely are filling up shelves at specialist companies, awaiting sale. Some never find a second life and must be properly disposed of.

Fortunately, there is a growing number of businesses emerging, filtering out select EV battery packs for applications such as home energy storage, grid batteries, generator replacement, EV conversions and so on.

Most EV battery packs can be safely opened and dismantled down to module level and, in some cases, cell level. This enables savvy businesses to repurpose them into just about any application with a demand. Modern EV batteries also boast some of the best energy densities – the likes of which the marine sector only sees on the horizon.

I have been a keen user, beneficiary and advocate of repurposing these batteries – but the marine industry is yet to widely exploit this supply of second-life, high-quality, low-cost batteries. Rehousing repurposed EV batteries in a marine environment is certainly within our capabilities, and greater challenges can be imagined: getting the necessary approvals and sorting in terms of class type certification, for example.

Another important consideration is lifecycle analysis and the carbon debt inherited by the new vessels’ manufacturing processes. Batteries need to be used across their lifetime to ensure all the energy used to manufacture them does not go to waste.

So, in the case of recreational electric vessels, they see little use and struggle not to increase their carbon debt. Install second-life lithium batteries, however, and we take one more step to clearing up any thoughts that zero-emission vessels might be bad for the planet.

Global demand for lithium batteries is ever increasing, and it’s fair to say raw materials have become a sought-after (hopefully not fought-after) commodity. Essential, established industries often get first dibs on raw materials or the finished product. At present, demand from marine applications is low, but embracing repurposed batteries (on the way toward mainstream adoption) is an opportunity for the marine industry to further decarbonize, benefiting from an alternative battery supply solution and remaining competitive.

The EU Battery Regulation entered into force in August 2023, with a digital battery passport becoming mandatory from February 2027. This will enable all batteries to be tracked from assembly to recycling, and further pressure industries to make full use of them.

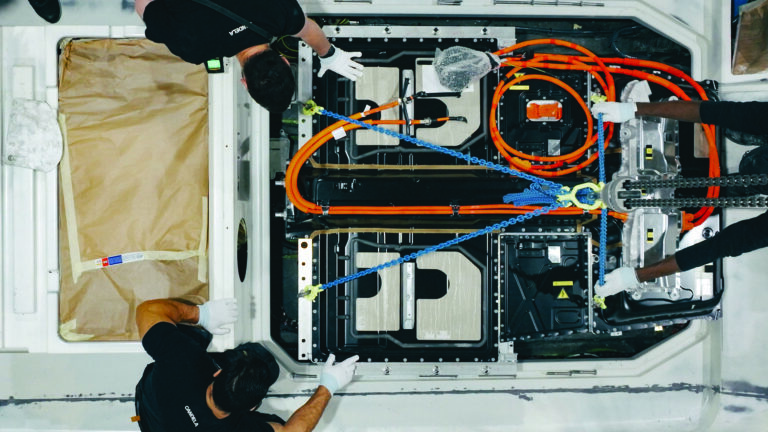

The electric and hybrid marine industry has already seen vessels benefiting from new EV battery packs, such as Torqeedo’s BMW i3 battery used in its Deep Blue systems, Candela’s use of the Polestar 2 battery and the Frauscher x Porsche 850 Fantom Air using the auto maker’s 100kWh battery. Could the next step be for these vessel manufacturers to offer a lower-cost, second-life battery option?